Stratigraphy

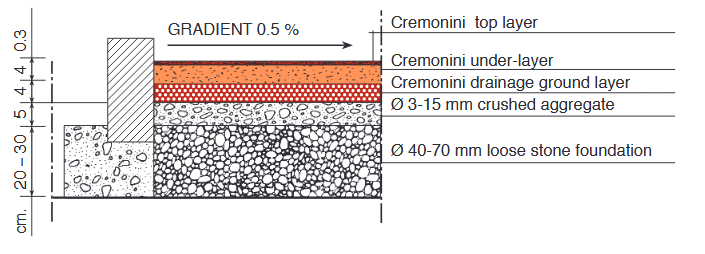

Here is an example of the stratigraphy a tennis clay court. The picture above is taken from the site https://www.cremoninisrl.it/. Before talking about clay, it is better to start from the base on which it will be placed. A tennis court needs a specific foundation in order to perform correctly. The stratigraphy, starting from the bottom, is usually divided into three layers:

- Loose stone foundation with variable thickness from 20 to 30 cm and grain size 40/70 mm;

- Crushed aggregate with an indicative thickness of 5 cm and grain size 3/15 mm;

- Drainage ground layer, also in this case with an indicative thickness of 4 cm and with a grain size of 0/15 mm.

Subsequently we will add:

- Tennis under-layer for at least 4 cm of thickness;

- Tennis top layer, just enough to cover the entire playing area like a veil. Usually no less than 4 quintals, equal to 16 bags of 25 kg.

How much tennis under-layer is needed?

Assuming that a classic tennis court has the size of 18×36 m, to obtain the 4 cm thickness of clay as per the technical data sheet, we will nned about 35/38 tons of it. How did I come up with this quantity? With the rule of 12.

The rule of 12

12 kg of tennis under-layer are required to raise the surface of 1 square meter of court by 1 cm. So once the area of the surface to be worked has been calculated, which is 18×36 m, we multiply the result by the 12 kg of tennis under-layer and we get the amount witch we needed to thicken the court by 1 cm. To complite the calculation, let’s then multiply by the 4 cm of thickness that a standard court requires. The result is 31 tons (31.104 to be exact). At this point I add a variable: the compaction of the clay. In fact, once wet and pressed, tennis under-layer loses volume from 15% to 20%. This means that at the end of the process the final thickness that you will obtain could vary from 3.4 cm to 3.2 cm, which are not the 4 cm assumed at the start. To be congruous I must therefore add more tennis under-layer, and the 380 tons mentioned above would allow me to get this result.

What is the tennis top layer for?

The tennis top layer:

- Has an aesthetic function;

- It allows the player to “slide controlled” during the game;

- Slows down the premature damage of the court;

- Limits water evaporation, keeping the playing surface more elastic.

What is the difference between the tennis under-layer and the tennis top layer?

The tennis under-layer is composed of crushed brick with the addition of raw clay, while the tennis top layer is only crushed brick. The raw clay therefore has “binding” characteristics that the tennis top layer does not have. Basically this is enough to get started, but there is much more to learn.

How to proceed with the laying of the tennis under-layer

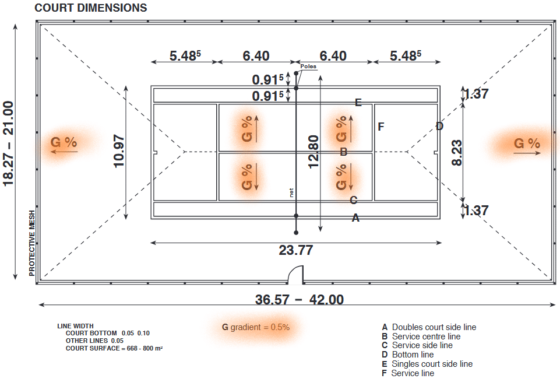

The layers of the loose stone foundation, crushed aggregate and drainage ground, must be suitably pressed and leveled to obtain the flatness required before adding the tennis under-layer. A 0.5% gradient from the center of the court towards the side, must be respected as shown in the picture below. This is to help the drainage of rainwater and avoid stagnation on the playing surface, which would make the court unusable. For obvious reasons, the perimeter fence is mandatory. Without it, the clay would spread outside the area, compromising the integrity of the court over time.

At this point, “tracks” are created with the help of flat-base aluminum slats 4 to 5 cm high. The clay will be poured into the “tracks”, which will be subsequently leveled using a float, which can be alluminium or wood. The surface that will be created will follow the natural slope. The drafting of the tennis under-layer must always be done when it is dry. The wet tennis under-layer is difficult to spread and once dry it creates imperfections. This work must be done in dry wheater, preferably in the sun, and in any case in 2/3 days without rain.

Rolling

The first rolling must be performed after having thoroughly wet the entire surface of the court. In order to wet it properly you need to saturate it with water and to do so you don’t need to be in a hurry. It can even take hours. The right roller for this type of processing must be at least 300 kg, but it can go up to 500 kg ballasting. If it is a motorized roller it is obviously better. If the roller cylinder does not remain wet while moving, it means that the court is not wet enough and it is not working well. It is therefore necessary to stop and start again with the hose. At the end of the first roll, the surface will highlight any low areas that must be fixed by adding more the tennis under-layer until flatness is restored.

Water, pressure and sun

Water, pressure and sun is all that is needed to have the consolidation phase of the court under control. The continuous rolling compacts the surface and the raw clay in tennis under-layer performs its function as a binder. The evaporation of excess moisture, results in an elastic but steady court. The court needs a running-in phase before using it intensively. Usually you start with tennis schools, and later all the others.

Surface maintenance

It is essential to follow the maintenance rules for a clay court if you want it to last. Watering several times a day, every day. Rolling as needed and fixing the holes represent the “ABC” of the maintenance technician. Then, with experience, the techniques and tricks will be refined so that the court performes better with the minimum effort.

Note

As always, this document represents my point of view based on my acquired skills. I am not a builder but a maintainer. With this article I am answering specific questions asked to me by my friend Sanket from India.